Inspect First - Then Refurbish

In recent years, the number of artificial pitches used to practise sports has continued to increase, largely replacing old surfaces such as ...

YOUR FORUM FOR PLAY, SPORTS UND LEISURE AREAS

Bound elastic shockpads are known to be bound elastic PUR layers made of rubber granules/fibres and grains of stone. According to the German standard DIN V 18035-7 (revised version 2011 draft) they must ensure the bearing capacity and resilience of synthetic turf pitches. The design for these elastic layers is curious in that it is not known where the layers originate from, how they are made or how they are defined, i.e. the range of grain size and the mixing ratio of the two components. These questions are also not taken into consideration or documented in the test procedures for actual elastic shockpad products. Requirements are only given for their thickness, shock absorption, strength and permeability to water.

Currently no systematic studies of the properties of elastic shockpads have been published. So how can we be sure that this kind of elastic layer “ensures” the bearing capacity of a sports surface? To fulfil this requirement, it is now intended to introduce the parameter “flexural stiffness”. It is correct that this is the property which causes an improvement in load bearing capacity of the design, but it is not necessary to test this property specifically (in dependence of ISO 178 – whatever that means). From an elastic-mechanic point of view, the stiffness is determined by the resilience (included in the parameter shock absorption) and the thickness of the layer.

In this way, introduction of the new parameter will lead to all existing test reports becoming useless, and will make new testing necessary. This will not create any improvement in the quality of bound elastic shockpads.

The story of how bound elastic shockpads were created may shed some light on the importance accorded to them in the manufacture of synthetic turf surfaces. Elastic layers made of a mixture of rubber particles, grains of stone and PUR binding agents were invented and patented in Switzerland in 1977 (patent no. 601567). This system replaced the already existing system using normal grains of stone with foamed clay which provided advantages for the more consistent manufacture of bound elastic layers (dryness).

A possibly independent development was initiated with the manufacture of Porplastic layers in 1982/83. These covering layers were made of grains of stone to which a certain amount of rubber particles were added and then bound with bitumen. Elastification additives were added to the binding agent so that a limitedly flexible layer was created. The top layer was made up of a loose, approx. 15 – 20 mm thick layer of bitumen-coated sand. This design system remained quite popular throughout the 1980s.

In some building projects in Southern Germany it was attempted to use an elastic binding agent instead of the bituminous products. This idea was taken up by a regional financial director, a certain Mr. Hofmann, and bound elastic shockpads were introduced as surfacing material, with the application of only an injected top coating, for athletic running tracks for the German military services. The thickness of the elastic shockpad was determined by the fact that with large-scale application systems, only thicknesses of at least 35 mm could be applied. The advantage of this construction method was considered to be the fact that the elastic shockpad replaced the asphalt layer. Although this development was subject at that time to severe criticism from some quarters, it was quickly adapted by the industry. Some companies, who had not installed Porplastic covers before this, purchased the corresponding large mixing and installation equipment (i.e. to be transported with low loaders), which provided them with a significant competitive advantage compared to the traditional construction methods. Use of this kind of elastic layer under synthetic turf materials is standard procedure today. Elastic shockpads have not been as successful, however, for installation under synthetic surfaces (running tracks and all-weather pitches). Introduction of the requirements given above will create the necessary parameter in order to ensure their suitability for use.

In practical use the mixing ratio of the additives is approx. 1:1. This means that due to the different bulk density of the materials, the weight percentages are around 30:70. If the binding agent content of a normal elastic layer is assumed to be 12%, an equivalent binding agent content for this kind of elastic shockpad would be around 7%. The hardest known variety of elastic shockpad is a combination of 44kg stone chips to 4.5kg styrene-butadiene-rubber with 2.6kg PUR binding agent (binding agent content : 5.4%).

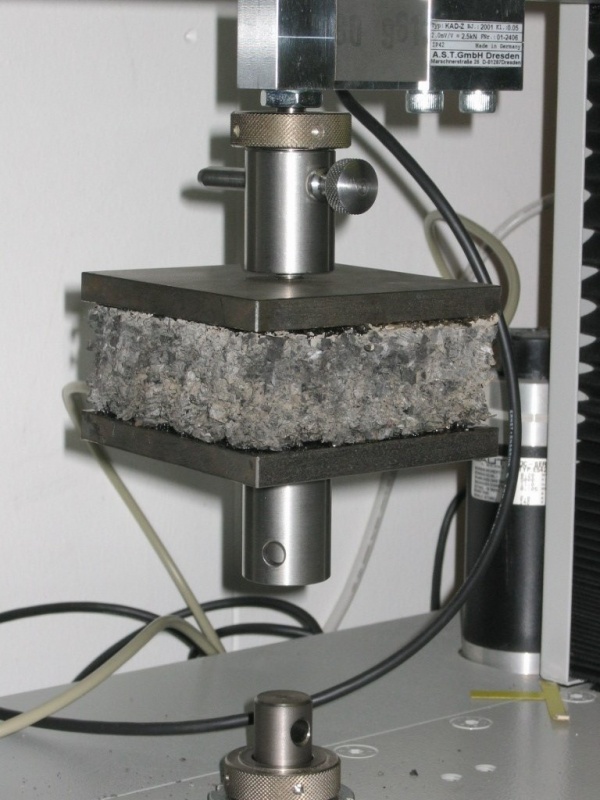

Practical experience has shown that to all intents and purposes, bound elastic shockpads may exhibit the necessary property requirements. One difficulty which arose during the strength tests was that due to the stone chip content of the material, no shoulder bar samples could be cut or sawn for conventional tensile tests. This problem was solved with the development of transverse tensile testing (see photos). According to this test method, 10x10cm test samples are sawed out of the material. The stones from the mineral base layer are carefully removed from the uneven lower side of the test sample (both manually and mechanically) and it is trimmed mechanically so that parallel top and bottom sides are created. The test sample is then glued to a steel plate using two-component epoxy adhesive. This adhesive fills the cavities on the uneven surface of the sample and forms a secure bond over the whole sample surface as it also enters some of the lower pores without actually penetrating the whole sample. After curing of the adhesive the sample is turned over and bonded in the same way to a second steel plate. After curing of this second bond the sample is subjected to transverse tensile tests in that both steel plates are clamped into the tensile testing machine instead of using the usual clamps. This testing method has been tried and tested and has proved its value over the years for both laboratory samples and those taken in field experiments.

The following points are important with regard to bound elastic shockpads:

1. The material for bound elastic shockpads is generally mixed with modified asphalt mixing equipment. This involves the mixing materials being transported with multi-axle trucks over the unprotected mineral (loose) base layer to the mixing equipment. This is only acceptable if the mineral base layer is very stable as otherwise, tracks are formed leading to uneven thicknesses of the elastic layer. If mixing is carried out with smaller-scale equipment, the installation work takes up to five times longer.

2. From an environmental point of view, the use of bound elastic shockpads contradicts the basic principles of waste separation. This is due to the fact that during recycling of such an elastic layer, the rubber content cannot be separated from the stone chips. For this reason, “recycling” is carried out in a practical way, i.e. the elastic shockpad material is shredded in the same way as asphalt surfaces and used as an additive for backfill material.