Inspect First - Then Refurbish

In recent years, the number of artificial pitches used to practise sports has continued to increase, largely replacing old surfaces such as ...

YOUR FORUM FOR PLAY, SPORTS UND LEISURE AREAS

Along with construction and maintenance costs, intensity of use is an important factor for selection of a suitable sport surface. Reference literature assumes up to 1500 hours of use for a dirt sports area. Taken relatively, this means that a dirt pitch is used for more than 4 hours a day, 365 days a year. Realistically speaking and taking into account holidays, bad weather etc., a frequency of use of 5 – 6 hours in the summer season and 2 – 3 hours in the winter season can be assumed. At this point, however it must be differentiated between a possible use amounting to 1500 hours / year and the actual use. Actual use is dependent on a range of different factors such as the size of the club, number of teams, possible alternative pitches, use for school sport, etc. Accordingly, this can only be determined in a specific project. It can be generally assumed that a sport surface which is mainly used during half a day will practically never achieve the possible hours of use of a dirt pitch.

Dirt surfaces are not all-weather pitches and are therefore, very susceptible to the influence of the weather. During rainy periods use is limited due to softening of the surface. In some cases during periods of freezing / thawing or very heavy rainfall the pitch may even need to be closed. On the other hand, the pitch surface will harden over time which greatly reduces permeability to water but also increases the risk of injury. With the implementation of suitable measures – and this one of the major advantages of ash or dirt pitches – the surface properties can be improved again so that in contrast to a turf pitch, the duration of use can be extended.

As with all other sport surfaces, correct maintenance and care of a dirt pitch plays a significant role. This means that work must be carried out by correspondingly trained personnel as with the wrong care, any surface can be destroyed within a short space of time.

The intensity and frequency of use of dirt pitches are dependent on the factors kind of material (slag, waste stone and/or natural stone material), frequency of use, weather conditions and topography. The maintenance work required for a dirt pitch mainly levelling of the surface layer, watering and rolling.

Levelling of the surface layer is very important for maintenance of the sport-functional properties of the pitch. Irregularities caused by use are ground in using suitable equipment. This equipment should have a working width of between 1.5 and 2.5 metres and must be heavy enough that it does not “jump” while not being too heavy and causing damage to the playing surface. Equipment such as construction steel mats, drag nets, aligned profile section strips connected loosely or rigidly and drag beams with steel edges. Wherever possible, levelling should be carried out crosswise at speeds not exceeding 15 km/h. When driving in curves, the speed must be greatly reduced to prevent the surface layer from being displaced.

All dirt pitches are mechanically stabilised, water-bound surfaces which means that when no or only little water is contained in the surface layer, it is no longer bound. Based on this, the surface must be watered during dry periods. In new facilities this is most efficiently carried out by the installation of an underground irrigation system. In any case, the number of sprinklers must be chosen so that approx. 10 litres of water per square metre in two doses can be sprayed although the actual requirement is dependent on weather conditions. In dry weather it is better to dampen the pitch before each use and especially before intensive use. On principle, dirt pitches should only be used and worked on in a slightly damp condition in order to reduce destruction of the grains and the risk of injury as far as possible.

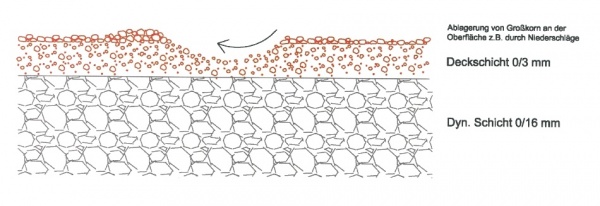

Particular attention must be paid to repair of damage as it occurs and manual maintenance before each use of the pitch. If this is not carried out sooner or later the whole pitch substrate will be impaired. Figs. 1 – 3 show cause and effect of damage in greater detail. Repair of holes must first be carried out manually. If mixing of the surface and dynamic layer has already taken place, this mixed material should be removed before filling of the dynamic layer using replacement material with a grain size of 0/16 mm which is then damped. The surface layer is then filled with damp material with grain size 0/3 mm and damped, for example with a hand tamper.

Especially during the period at the end of winter, beginning of spring, it is possible that the frozen playing surface thaws while the dynamic layer and substrate remain frozen. This phase is also known as frost-thaw cycle and during this period, surface water cannot run off so that the surface layer contains a large amount of water. Use of the pitch in this condition would lead inevitably to destruction of the surface layer. When the whole pitch construction has thawed, the surface layer should be compacted in a damp state by cross-wise rolling. Only then can the pitch be played on again. The optimal compacting roller weight lies between 4 and 6 kg/cm². When using rollers, whether automatic or vehicle-drawn, care must be taken that they are segmented to allow curves without damage to the pitch and that the edges are rounded. The rollers should be at least 30 cm in diameter in order to prevent the surface material from being displaced. Successful compacting of the surface layer can only be achieved if it is sufficiently damp, too much water on the other hand, can result in too strong compaction of the pitch which prevents water permeation.

Examination of older dirt pitches has shown that the thickness of the covering surface layer tends to decrease from the edges towards the middle of the pitch. In addition, the quantity of silt and poor-quality surfacing increases, leading to stronger compacting of the pitch, reduced elasticity and lower water permeability.

When the surface layer becomes compacted in this way, it must be carefully loosened again using special equipment with prongs which penetrate the surface up to, but not more than 1 – 2 cm to prevent the coarse material of the dynamic layer being brought to the surface. Photos 2 and 3 show examples of this kind of equipment

If sufficient water permeability cannot be achieved with these measures, the possibility exists of aerating both the covering and dynamic layers with solid spoons. Following this, the holes created are filled with supporting grains whereby a transfer of grains and silt into the supporting layers may occur resulting in a disadvantageous change in substrate properties and reduced permeability of the supporting layers.

Along with the inexpensive construction costs, the different renovation possibilities present the greatest advantages of dirt pitches. Further advantages are created however, for all those involved in the construction of the dirt pitch. In contrast, for example, to a synthetic turf pitch, the parameters which have an influence on the quality and life-expectancy of a playing surface, such as grain distribution, shear strength, water permeability etc., can be tested on-site to achieve approval. In this way, the owner has greater clarity and more reliable results showing what has actually been installed. In this way, suitability tests carried out by manufacturers do not present the only security for product quality. Construction procedures, and therefore, the corresponding suitability, surveillance and control tests are laid down in the standard DIN 18035-5 which was issued in the latest and revised version in August 2007.

Based on the difficult financial situation of many communities and the continued requirement for sport facilities, dirt pitches should be given more attention whereby the actual period of use of the pitch must be taken into account and not the theoretically possible use. Professional care and maintenance work is required for all sports surfaces, although in contrast to synthetic turf surfaces, the life expectancy of dirt pitches until they are deemed to present too great a risk of injury for users, can be greatly increased through the implementation of corresponding renovation measures.

Photo 1

Football is still played on dirt pitches. The different colouring of the dirt surface indicates that the pitch has been watered.

Photo 2

Groundcare equipment for loosening the surface layer. Compacted surface material can be loosened using a combination of spiked and grid rollers.

Photo 3

Further maintenance equipment for treating the playing surface. A vibration harrow is combined here with a spiked roller before the loosened material is pressed with a smooth-surfaced roller.

Photo 4

Use of VertriDrain equipment on a dirt pitch. The solid spoons break through the surface and dynamic layers into the substrate.

Fig. 1

Illustration of punctiform treatment. The covering layer material is brought to the surface and mixed.

Fig. 2

Without previous removal, mainly coarse material is transported into the passage during levelling. Due to the separation, this material cannot be sufficiently compacted.

Fig. 3

Due to insufficient strength of the separated material in the following passage, the equipment can reach into the dynamic layer and coarse material from the dynamic layer is brought to the surface. Along with destroying the substrate of the pitch, this also represents a danger of injury to players.