Inspect First - Then Refurbish

In recent years, the number of artificial pitches used to practise sports has continued to increase, largely replacing old surfaces such as ...

YOUR FORUM FOR PLAY, SPORTS UND LEISURE AREAS

Compliance testing of synthetic turf pitches

Dipl.-Phys. Bernd Härting, Institut für Sportbodentechnik Leipzig (IST)

Until October 2011, the standard DIN V 18035-7:2002-06 was the sole technical reference for manufacture of synthetic turf pitches in Germany. The DIN authorities have now withdrawn this standard and replaced it with DIN SPEC (pre-standard) 18035-7:2011 Sports grounds – Part 7: Synthetic turf areas, which is not a standard in the sense of DIN standard specifications.

The valid DIN standard for testing of synthetic turf areas in Germany is DIN EN 15330-1:2008-01 Surfaces for sports areas – Synthetic turf and needle-punched surfaces primarily designed for outdoor use – Part 1: Specification for synthetic turf.

As in DIN V 18035-7, in DIN SPEC 18035-7 it is also differed between suitability tests, quality control and testing.

Under point 6.1.4 Compliance testing it states:

"Tests are requested by the ordering party. The scope and minimum number of tests for each layer or the synthetic turf system is determined in the individual segments."

In DIN SPEC 18035-7 however, no tests are foreseen for the finished synthetic turf pitch and no special requirements are given for important user parameters such as shock absorption, ball rebound, ball rolling behaviour, etc. With this unusual provision that a standard does not apply to the finished product, but only to laboratory samples of the building material used, general contractors have been left with no way of evaluating the performance of a supplier. Agreement to this ruling by the consumer representatives in the work committee is incomprehensible.

In the commentary to the VOB (German construction contract procedures), Section C: General technical specifications in construction contracts – Landscape work, the following statement is made concerning compliance testing:

"Careful and comprehensive carrying out of compliance testing is an explicit obligation for the general contractor within the framework of his construction supervision. Only with the help of the compliance tests can a proper evaluation of the contractually agreed performance of the supplier be ensured and, therefore, prerequisites for flawless approval be created. If existing faults are not recognised before or during acceptance procedures due to a lack of or incomplete compliance tests, the burden of proof lies completely with the general contractor for faults which only become visible after acceptance."

And further:

"All compliance tests also include, as far as necessary,

- taking of samples

- packaging of samples for transport

- transport of samples from the place they were taken to the testing site

- carrying out testing (on samples at the testing site, with building site tests, on the building site)."

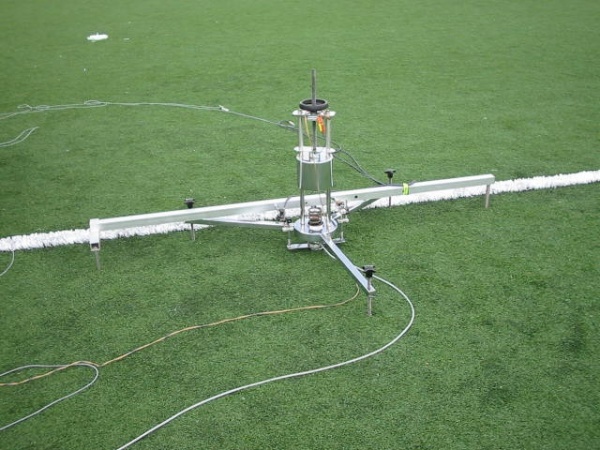

For testing of finished surfaces, therefore, procedure as per Appendix A "On-site testing" of DIN EN 15330-1:2008-01 is recommended for tendering offers. This foresees the following field tests for football, hockey and combined hockey and football pitches carried out at the five determined testing locations:

Ball rebound (with a hockey and/or football)

Ball rolling behaviour (with a hockey and/or football),

Shock absorption,

Vertical deformation,

Rotational resistance and

Water permeability

According to information from the DIN authorities, application of DIN EN 15330-1 and DIN SPEC 18035-7 for field tests do not rival but complement each other without having the same status.

In the DIN SPEC, testing of the strength of the elastic layers (elastic supporting layer) is not sufficiently defined. The tests of tensile and transverse tensile strength have been omitted and replaced by determination of the torsion strength which, according to tests carried out by the technical college of Osnabrück, are critical (see sb 02/2012, pages 52 and 53). For this reason it is urgently recommended to continue to request determination of transverse tensile strength on samples taken with a specified value of at least 0.1 N/mm2.

Photo: deltecmetaal